Views: 0 Author: Site Editor Publish Time: 2025-01-04 Origin: Site

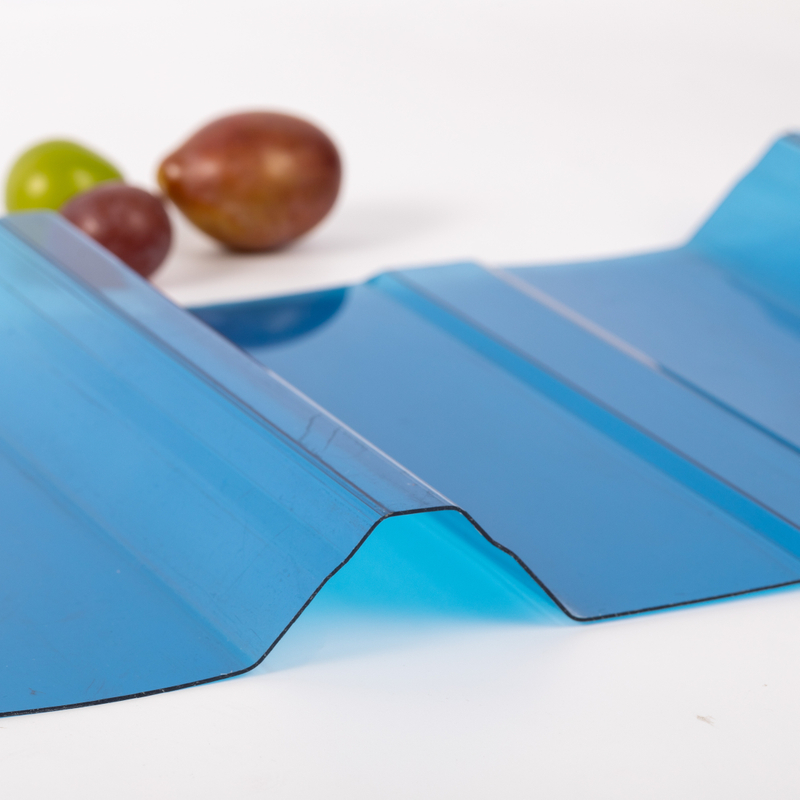

Polycarbonate sheets have become an essential material across various industries due to their durability, transparency, and impact resistance. Among the different types of polycarbonate sheets available, solid polycarbonate sheets and hollow polycarbonate sheets are the two most popular choices. Understanding the differences between these two options can help in selecting the most suitable material for a particular application.

In this article, we will compare solid and hollow polycarbonate sheets based on their key characteristics, benefits, and applications. We will also highlight their performance in terms of insulation, strength, impact resistance, and light transmission.

Hollow polycarbonate sheets, often referred to as polycarbonate multiwall sheets or twin-wall polycarbonate sheets, are designed with multiple layers separated by air pockets or voids. These sheets are ideal for applications where insulation and lightweight properties are necessary.

| Characteristic | Hollow Polycarbonate Sheets | Solid Polycarbonate Sheets |

|---|---|---|

| Structure | Multi-layer, air pockets or voids between layers | Single, solid layer |

| Thermal Insulation | Excellent thermal insulation due to air pockets | Good thermal insulation, but less effective than hollow sheets |

| Light Transmission | High light transmission, depending on sheet thickness | High light transmission, clear optical properties |

| Impact Resistance | High impact resistance, but not as strong as solid sheets | Superior impact resistance, ideal for safety applications |

| Weight | Lightweight due to internal voids | Heavier, more rigid |

| UV Protection | UV-resistant coatings available to prevent degradation | UV-resistant coatings also available for protection |

| Environmental Resistance | Excellent resistance to weather and aging | Strong weather resistance, but slightly more prone to degradation over time |

Thermal Insulation: The air pockets inside hollow polycarbonate sheets provide excellent insulation, making them perfect for energy-efficient applications. They help to maintain a stable indoor temperature by reducing heat transfer.

Light Transmission: These sheets allow a significant amount of light to pass through, making them an excellent choice for structures that require natural lighting, such as greenhouses and skylights.

Impact Resistance: Although not as strong as solid polycarbonate sheets, hollow polycarbonate sheets still offer impressive impact resistance, making them suitable for safety-related applications.

Lightweight: Hollow polycarbonate sheets are much lighter compared to solid polycarbonate sheets, making them easier to handle and install. This is particularly beneficial in large-scale roofing or wall cladding projects.

Cost-Effective: Due to their lightweight nature and multi-layer structure, hollow polycarbonate sheets are often more affordable than their solid counterparts, especially in projects requiring large areas to be covered.

Superior Strength: Solid polycarbonate sheets are more rigid and have higher tensile strength than hollow sheets. This makes them more suitable for applications where structural integrity is critical, such as in safety glazing and impact barriers.

Optical Clarity: Solid polycarbonate sheets offer exceptional optical clarity and are ideal for applications where transparency and visual aesthetics are important.

High Impact Resistance: These sheets are much stronger and offer superior impact resistance compared to hollow polycarbonate sheets. They are often used in environments where the material is exposed to heavy impacts.

Long-Term Durability: Solid polycarbonate sheets are highly durable and are resistant to weathering, UV degradation, and chemical exposure. Their lifespan is generally longer than hollow polycarbonate sheets.

Temperature Stability: Solid polycarbonate sheets are less affected by temperature changes, making them a better option in environments with extreme conditions.

Hollow polycarbonate sheets are highly versatile and can be used in a wide range of applications, especially where insulation, lightweight properties, and UV protection are important. Below are some common applications:

| Application | Description |

|---|---|

| Polycarbonate Roofing Panels | Used for roofing in industrial, commercial, and residential applications. |

| Polycarbonate Sheets for Greenhouses | Helps maintain stable temperatures while allowing for maximum sunlight transmission. |

| Polycarbonate Panels for Walls | Ideal for constructing walls that need thermal insulation and light transmission. |

| Hollow Polycarbonate Panel Roofing | Used in outdoor enclosures, pergolas, and covered walkways, providing UV protection and insulation. |

| Polycarbonate Sheet for Skylights | Perfect for applications requiring a clear, transparent roofing material with added insulation. |

| Energy-efficient Polycarbonate Sheets | Helps conserve energy by reducing heating and cooling costs in buildings. |

Solid polycarbonate sheets are often used in applications where optical clarity, impact resistance, and strength are the primary concerns.

| Application | Description |

|---|---|

| Safety Glazing | Ideal for windows, safety barriers, and bullet-resistant applications. |

| Skylights | Provides high optical clarity and strength for applications requiring clear, strong light transmission. |

| Signage | Used for clear signage that requires durability and resistance to impact. |

| Architectural Design | Used in modern building designs for elements like windows, domes, and facades. |

| Protective Barriers | Ideal for fencing, shields, and other impact-resistant applications. |

To make an informed decision, it's helpful to compare the key performance factors of hollow polycarbonate sheets and solid polycarbonate sheets:

| Performance Factor | Hollow Polycarbonate Sheets | Solid Polycarbonate Sheets |

|---|---|---|

| Thermal Insulation | Excellent (better than solid sheets) | Good, but less efficient than hollow sheets |

| Light Transmission | High, but can vary with sheet thickness and finish | High, with clear optical properties |

| Strength | Moderate strength, ideal for non-critical applications | High strength, ideal for safety and structural integrity |

| Weight | Lightweight and easy to handle | Heavier and more rigid |

| Durability | UV-resistant and durable but may degrade over time | Longer lifespan with higher resistance to wear and tear |

| Cost | More affordable, cost-effective for large areas | More expensive, higher strength and durability |

Choosing between solid and hollow polycarbonate sheets depends on the specific requirements of your project. Hollow polycarbonate sheets are ideal for applications where thermal insulation, light transmission, and lightweight properties are paramount. They are cost-effective, provide excellent UV resistance, and are perfect for roofing, greenhouses, and wall cladding.

On the other hand, solid polycarbonate sheets offer superior strength and optical clarity, making them suitable for applications that require high-impact resistance, clarity, and durability, such as safety glazing and architectural design.

If you're considering hollow polycarbonate sheets for your next project, Pingyun International is your trusted partner. With over 20 years of experience in manufacturing high-quality polycarbonate roofing panels and polycarbonate panels for walls, Pingyun offers top-of-the-line solutions for all your construction and design needs. Visit www.pingyungroup.com for more information about our products and services.